Factors considered in selecting zirconium bead

-----------------------------------------------------------------------------------------------------------------------------------------

Filling quantity

-----------------------------------------------------------------------------------------------------------------------------------------

Some physical properties (hardness, density, wear resistance) determined by the chemical composition of the grinding medium and the pollution of its own wear to the slurry are the factors to be considered in the selection of grinding medium. Therefore, it is very important to choose a grinding medium that is more suitable for its own production process and conditions.

Filling quantity

The filling rate of grinding medium is directly affected by the filling rate of grinding medium (the filling rate of grinding medium is less than 40%).

Medium ratio

According to the types of grinding materials and process characteristics, select the appropriate medium filling amount to achieve the desired grinding effect with the lowest cost and the highest efficiency.

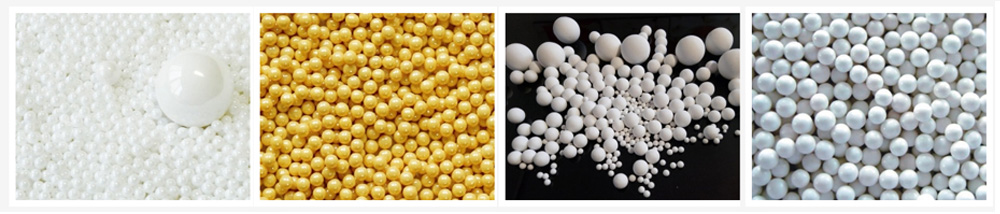

Shape and size

The size of the grinding medium ball directly affects the grinding effect and fineness, which determines the number of contact points between the grinding medium and the material. The more contact points of the grinding medium ball with small particle size under the same volume, the higher the crushing efficiency in theory.

Wear resistance & chemical stability

The wrong ball with stable chemical properties has higher wear resistance and impact resistance under the same conditions. It does not crack and peel off in high-speed and high concentration machines, with low wear, low power consumption, low comprehensive cost and no pollution to materials.

Medium density

The larger the specific gravity of the grinding beads, the greater the impulse, the higher the grinding efficiency, and the wear of the contact parts of the sand mill (inner cylinder, dispersion plate, etc.) is relatively large, so the matching of slurry viscosity and flow becomes the key. Low density grinding beads are suitable for low viscosity slurry, and high density grinding beads are suitable for high viscosity slurry. The higher the hardness of the grinding beads, the higher the density of the beads. The grinding beads are suitable for high viscosity slurry. The higher the hardness of the grinding beads, the lower the wear rate of the beads in theory.

texture of material

The difference of chemical composition of grinding media determines the different structure of grinding media, and then determines the different compressive strength and wear resistance of grinding media. The different content of components determines the density and hardness of grinding media.